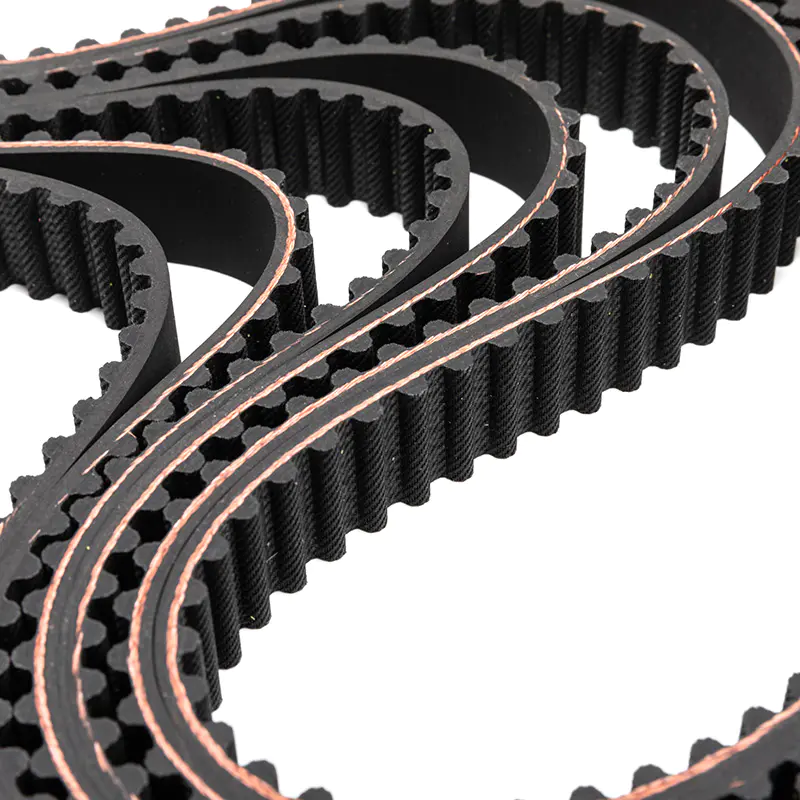

Precision and Efficiency: The tooth profile design is crucial for ensuring precise engagement between the timing belt and the pulley teeth. A well-engineered profile ensures that the teeth mesh smoothly without any backlash or slippage. This precise engagement is essential in automotive applications where timing accuracy directly influences engine performance, fuel efficiency, and emissions control. By minimizing play between the belt and pulley, an optimal tooth profile maximizes power transmission efficiency, ensuring that the engine operates at peak efficiency levels.

Noise and Vibration: The geometry and spacing of the teeth on the timing belt affect the levels of noise and vibration generated during operation. A carefully designed tooth profile helps to reduce oscillations and harmonics, resulting in quieter operation of the timing belt system. This is particularly important in modern vehicles where NVH (Noise, Vibration, and Harshness) levels are closely monitored to enhance passenger comfort and overall driving experience. By minimizing noise and vibration, an effective tooth profile also contributes to the longevity of the timing belt and associated components, as reduced mechanical stress helps to maintain their integrity over time.

Wear Resistance: The shape, depth, and material composition of the tooth profile significantly impact the wear resistance of CR rubber timing belts. An optimized profile design distributes the load evenly across the belt's teeth, minimizing localized wear and extending the operational lifespan of the belt. This even distribution of forces helps to prevent premature wear on individual teeth, which can lead to reduced performance and potential belt failure. By enhancing wear resistance, an effective tooth profile reduces the frequency of maintenance intervals and replacement cycles, thereby lowering overall operating costs for vehicle owners.

High-Speed Performance: Certain tooth profiles are specifically engineered to enhance performance at high speeds. These profiles are designed to minimize the risk of tooth jumping or belt flutter, which can occur when the belt operates at elevated RPMs. By maintaining consistent contact and engagement with the pulley teeth, an optimized tooth profile ensures smooth and reliable operation of the timing belt system under demanding conditions. This high-speed performance capability is critical in automotive applications where engine timing must be precisely controlled to optimize power delivery and maintain vehicle performance.

Load Distribution: The design of the tooth profile governs how loads are distributed along the length of the timing belt. A well-designed profile minimizes stress concentrations on individual teeth, ensuring that forces are evenly distributed across the belt's surface. This uniform distribution of forces helps to prevent localized wear and fatigue, which can compromise the durability and reliability of the timing belt over time. By enhancing load distribution, an effective tooth profile contributes to the overall robustness of the timing belt system, allowing it to withstand varying operating conditions and extended service intervals without compromising performance.

Compatibility: Tooth profiles are carefully engineered to be compatible with specific pulley designs and configurations used in automotive applications. This compatibility ensures optimal engagement between the timing belt and pulley, minimizing friction losses and maximizing power transmission efficiency. By selecting a tooth profile that matches the characteristics of the pulley system, automotive engineers can ensure reliable operation and reduced wear of the timing belt over its service life. Proper compatibility also helps to mitigate the risk of misalignment or improper engagement, which can lead to premature wear and potential system failures.

Hnbr Rubber Automotive Timing Belts

English

English 中文简体

中文简体

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>